|

|

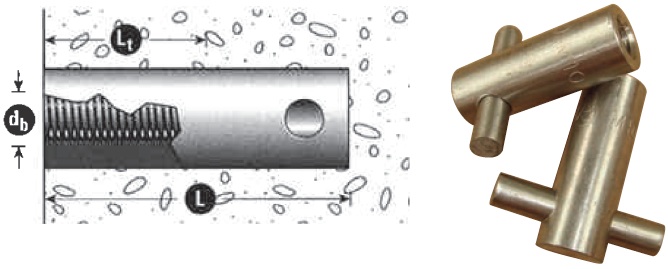

TCM Cast-In Anchors

Product Advantages

| > |

Stress free anchoring close to edge and reduced anchor spacing |

| > |

Cast-in placement eliminates the need for drilling, this is particularly important where reinforcing is present in the fixing zone |

| > |

Ideal for shallow embedment as the anchor can be tied into the reinforcement to distribute the load over a wider area to become an integral part of the reinforcing structure |

| > |

High tensile load carrying capacities as well as applications in tension zones |

Applications

| > |

Structural connections |

| > |

Curtain wall and facade fixings (concrete, GRC, etc.) |

| > |

Anchoring bracing and precast panels |

| > |

Concrete inserts can be set in wet concrete, attached into reinforcing through the cross hole or fastened to the inside of formwork with a bolt through the formwork. |

| > |

Drill hole in formwork. Pass the bolt through the hole into the concrete insert and tighten. Tie the insert to the reinforcing system. |

| > |

Pour the concrete. Remove the bolt and formwork leaving the concrete insert firmly embedded. |

Product Range

| Type |

Sizes |

| Zinc Plated |

M8 to M24 |

| Hot Dip Galvanized |

M8 to M24 |

| Stainless Steel A4 |

M8 to M24 |

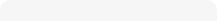

CIM Cast-In Anchors

Product Advantages

| > |

Stress free anchoring close to edge and reduced anchor spacing |

| > |

Cast-in placement eliminates the need for drilling, this is particularly important where reinforcing is present in the fixing zone |

| > |

Ideal for shallow embedment as the anchor can be tied into the reinforcement to distribute the load over a wider area to become an integral part of the reinforcing structure |

| > |

High tensile load carrying capacities as well as applications in tension zones |

| > |

Simple cost effective design with finish ranging from ZP, HDG, A2 and A4 |

Applications

| > |

Structural connections |

| > |

Curtain wall and facade fixings (concrete, GRC, etc.) |

| > |

Panel to panel connection |

| > |

High shear load appications |

| > |

Cooking bench |

| > |

Temporary precast panel bracing points |

| > |

Drill hole in formwork. Pass the bolt through the hole into the concrete insert and tighten. Tie the pin of the insert to the reinforcing system. |

| > |

Pour the concrete. Remove the bolt and formwork leaving the concrete insert firmly embedded. |

Product Range

| Type |

Sizes |

| Zinc Plated |

M6 to M24 |

| Hot Dip Galvanized |

M6 to M24 |

| Stainless Steel A2 |

M6 to M24 |

| Stainless Steel A4 |

M6 to M24 |

|

|

Product pages - Cast-In Anchors.pdf

Product pages - Cast-In Anchors.pdf